Reduce costs by optimizing asset management and inventory!

Improve the Asset Management and inventory process

increase control and responsibility

automate tracking and reporting

improve visibility and information analysis

The Digital Assets Management and Automated Inventory System (LIREX ASSETS) has been registered as a “utility model” with the Patent Office Commission under registration number 4158 U1.

increase control and responsibility

automate tracking and reporting

improve visibility and information analysis

You have many tangible assets that you need to periodically track and manage.

You spend a lot of time and money organizing this process. Errors are often made and that leads to complications. This is a real-life scenario in many organizations, but not in all!

Organizations that have modernized asset management and inventory are achieving cost optimization. This process is already highly efficient and innovative.

Optimized asset management and tracking

Minimizing the need for expert staff

Reduced missing assets and increased employees’ responsibility

Increased efficiency of investments in new equipment and inventory

Predictability of costs for available equipment and inventory

Optimizing the overall asset management process, including:

Optimizing the time required for inventory

Easy-to-use system with seamless access

Reducing human error factor

Effective management decisions based on easy-to-access reports

LIREX’s asset management and inventory system improve control, traceability and reporting of corporate assets. LIREX ASSETS provides the necessary tools for digital storage, search and retrieval of information on assets and inventories.

The system provides a tool for automated enumeration, as well as a mechanism for effective post-processing of inventory data to achieve accurate, correct and complete results with minimal effort.

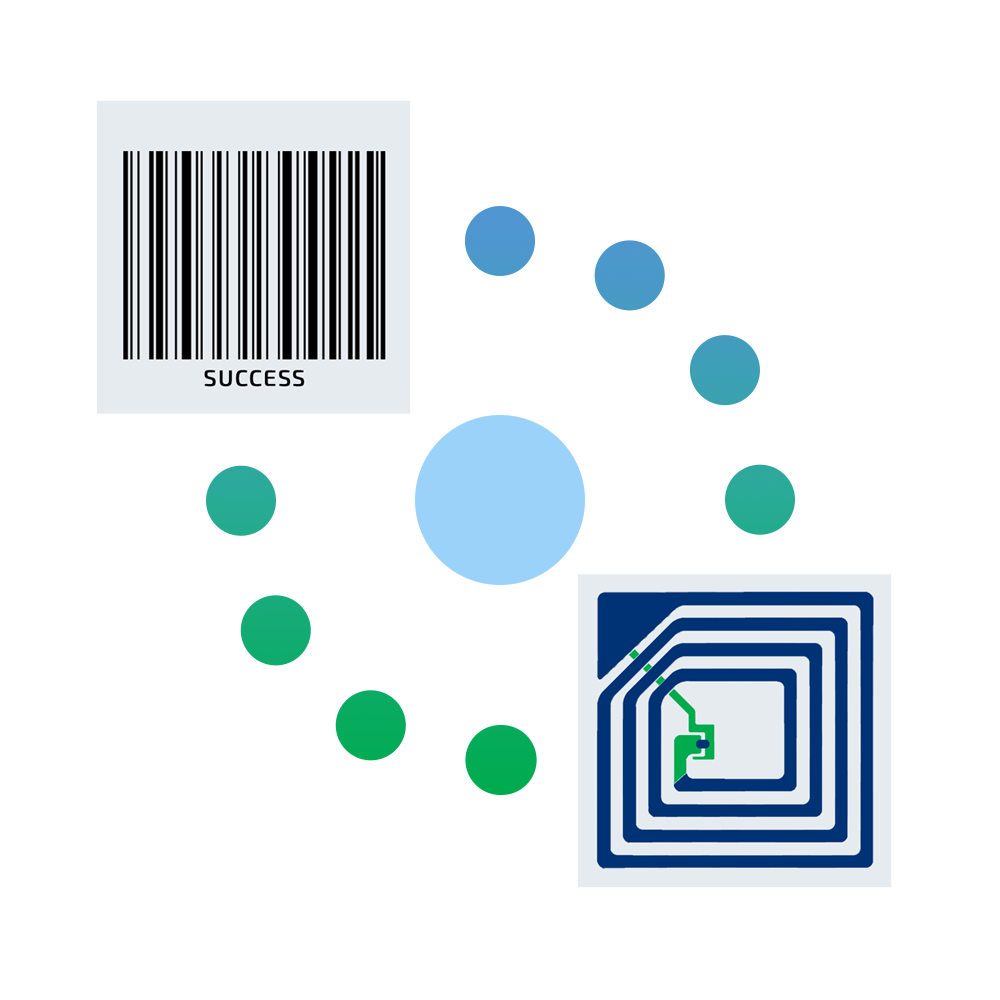

From a technological perspective, inventory can be done in two ways:

Barcode reader-based technology: With this technology, each asset is marked with a barcode with a unique identification number.

RFID tag technology: With this technology, each asset is marked with an RFID tag, which is more reliable and allows a more efficient inventory process.

RFID tags provide the ability for a fully automated inventory process. Each room is marked with a tag containing information about the assets to be found.

Each tangible asset in the room is also marked with a tag and during inventory with a mobile reader, it is checked whether the item is present. In case of a missing asset, the system alerts and gives complete information about the missing item.

By using a mobile reader, the inventory process can be done only by entering the room, without physically scanning the RFID tag.

As opposed to using RFID, when using barcodes to track an item you need to bring the reader directly facing the barcode itself so it can be read and counted

LIREX’s asset management and inventory solution is compatible with both technologies, enabling both to be used simultaneously.

The Asset Management and Inventory System by LIREX can be modified to the specific needs of your organization and various functionalities can be added or removed. At LIREX, we only offer what you need, without paying for features that are not relevant to your business. Our personalized consulting approach guarantees quality performance.